It has been a quiet period but a very busy period, very active and very fruitful. I will be launching the projectryu.com site soon with tons of free resources for the audio hobbyist.

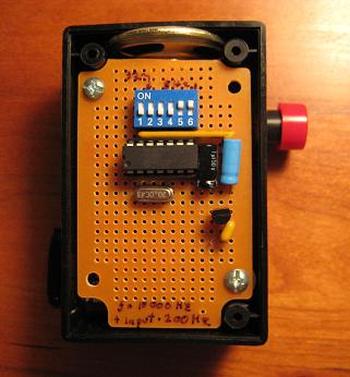

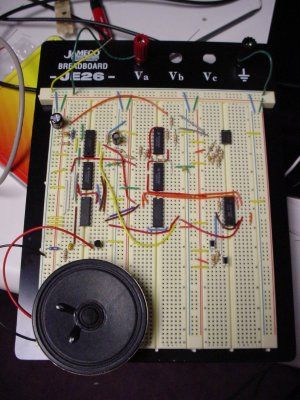

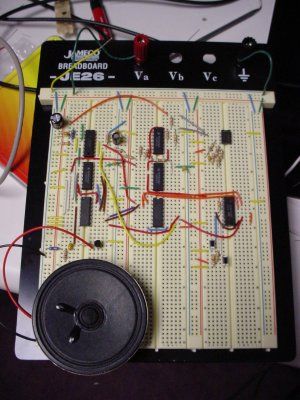

Getting back to the title of this post, i would like to present a few improvements and a concrete design as a pedal unit. If you don’t remember about the Lagger project let me put the links below in case you want to check it out.

As a quick summary, Project Ryu Lagger is a guitar effect pedal that slows down the attack of the guitar (or any instrument for that matter) just like an automated volume pedal.

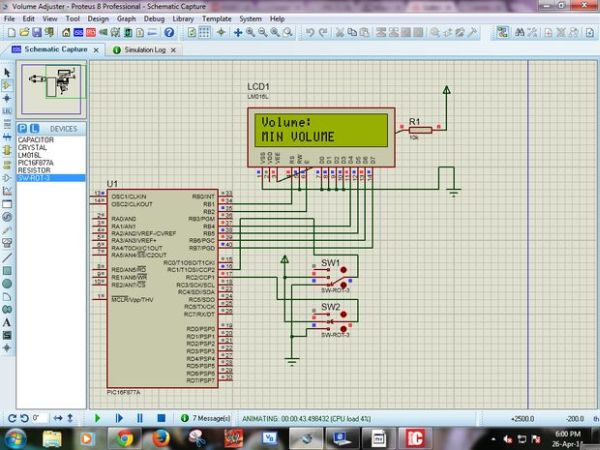

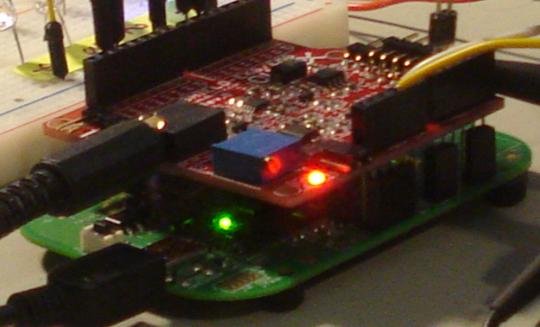

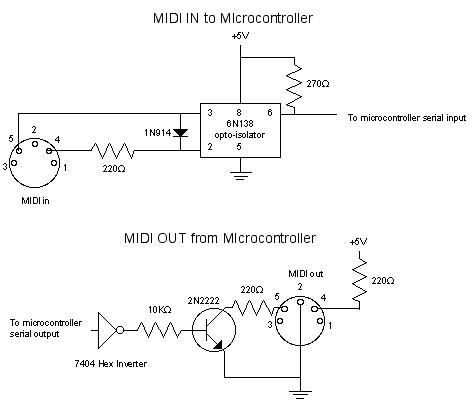

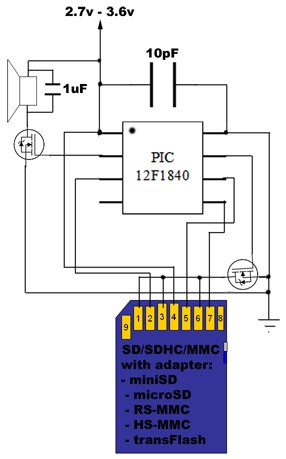

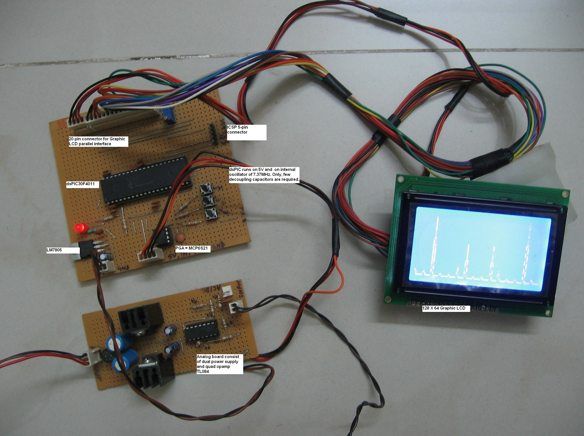

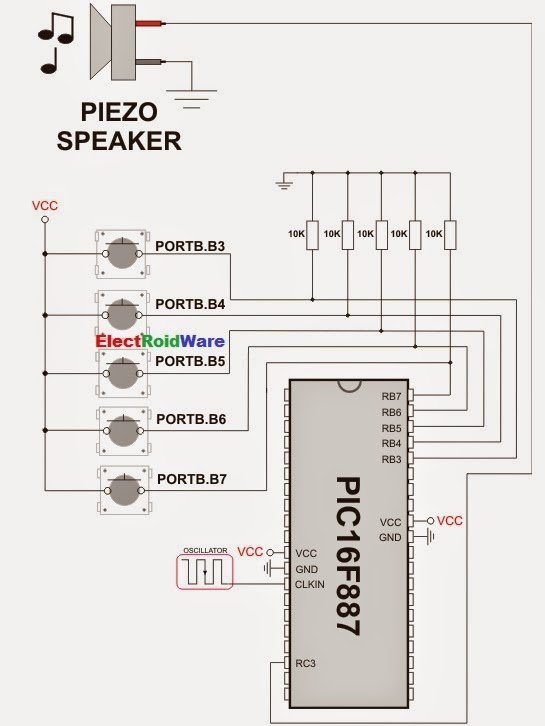

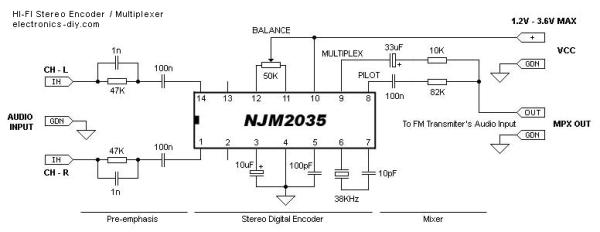

It does this with a VCA (Voltage Controlled Amplifier), based on the LM13600/LM13700. The fade in envelope is created with a ramp voltage generator that controls the VCA and this generator is triggered by a digital circuit created with a Microchip PI18F1320 MCU.

The digital signal conversion and rectification is explained in a previous article, please read it at the link below:

![Project Ryu Lagger Guitar Pedal Take 3]()

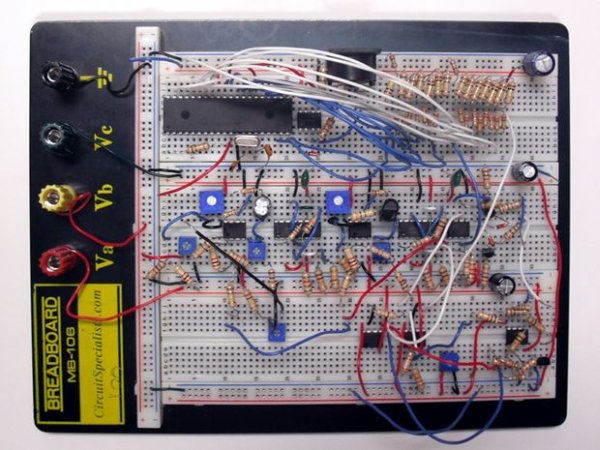

The new version i will present today was adapted as a real pedal with a 3 pole footswitch.

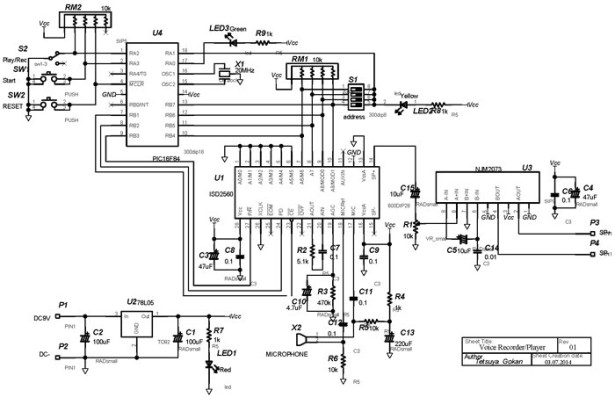

Another change was in the ramp generator replacing the 100k potentiometer with a 10k one since the other two pots in the circuit are 10k. This last change also implies changing some capacitor values. Please refer to the new schematics below:

Project Ryu Lagger Schematics

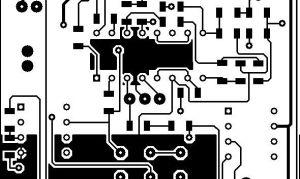

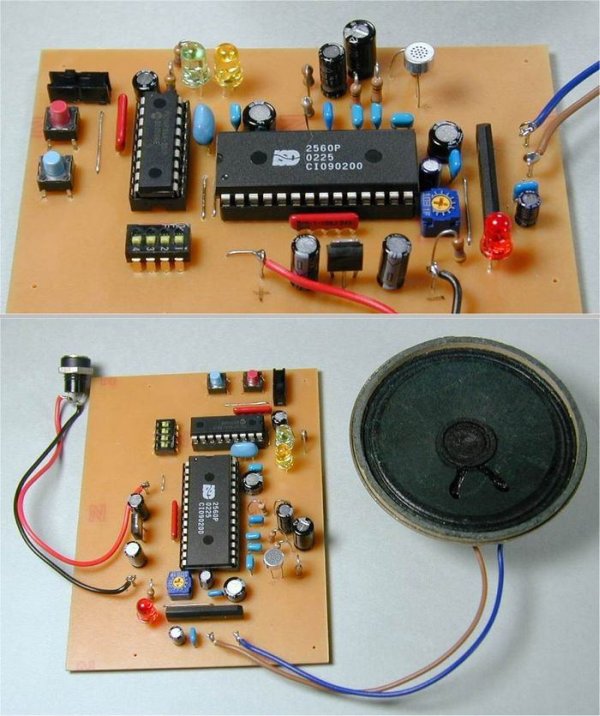

I am pretty satisfied with this pedal so i have created the PCB for this circuit. The PCB gerber files and the MCU firmware is available for free as usual to subscribers in the next newsletters. If you are not a subscriber yet please register in the form to the right.

Some things to consider if you plan to design your own PCB is good shield of the LM13600/13700 input pins. It is good to surround it with ground plane like below:

You can find the PCB artwork below:

Project Ryu Lagger PCB Art

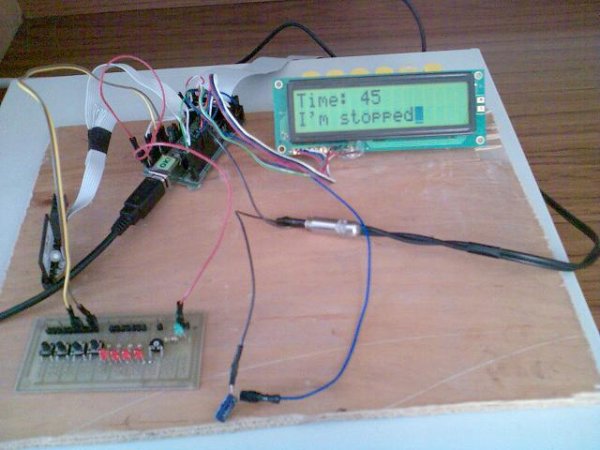

With the new modifications on the ramp generator circuit the min – max values for attack control is 0.1s and about 1.4s. Below is the ramp waveform measured, this is actually the control voltage of the VCA:

1. full counter clockwise attack pot setting:

Horizontal resolution: 50ms/div

2. full clockwise attack pot setting:

Horizontal resolution: 200ms/div

Below is a screenshot that shows the triggering of the ramp generator, the red trace is the input signal:

As you can see modifying the attack control will adjust the length of the fade in effect. The trigger control adjust the input level above which the ramp generator is triggered. This is to prevent noisy pickups or other pedals used in front of the Lagger to trigger the effect.

The level control adjusts output gain from between +6dB to a max of +24dB so it is capable of a high amount of gain. In the measurement below voltage gain is 14 with an output voltage of 3.6V peak to peak (yellow trace). As you can see there is a bit of saturation happening.

Bellow are two videos showing signal traces using sine waves at 1kHz, one video triggering the effect manually and the other with the effect triggered by the input signal.

Project Ryu Lagger is one of my favorite pedals, i really like this effect and the latest version allows for a great deal of control for the guitarist in sustaining the effect or muting by simply applying muting effects with the palm for example.

For DIY-ers this project is of moderate complexity but you can subscribe or comment here and i will try to offer any assistance i can. Remember to read the Disclaimer though.

Here is the parts list for this project:

| Quantity: |

References |

Value |

| 3 |

C1, C8, C15 |

4.7u |

| 2 |

C2, C3 |

22p |

| 1 |

C4 |

10u |

| 1 |

C5 |

100u |

| 2 |

C6, C7 |

33u |

| 1 |

C9 |

4700u |

| 1 |

C10 |

10u |

| 2 |

C11, C12 |

1000u |

| 5 |

C13, C14, C16-C18 |

100n |

| 2 |

R1, R21 |

2k |

| 13 |

R2, R6-R12, R15, R22, R23, R26, R28 |

10k |

| 1 |

R3 |

22k |

| 1 |

R4 |

3.3k |

| 4 |

R5, R29, R31, R32 |

2.2k |

| 3 |

R13, R14, R24 |

100k |

| 1 |

R18 |

1k |

| 1 |

R19 |

470 |

| 2 |

R20, R25 |

200 |

| 1 |

R27 |

5.6k |

| 1 |

R33 |

1M |

| 1 |

U1 |

LM13700 |

| 1 |

U2 |

PIC18F1320 |

| 1 |

U3 |

78L05 |

| 1 |

U4 |

79L05 |

| 2 |

U5, U6 |

TL071 |

| 2 |

Q1, Q2 |

BC549 |

| 1 |

Q3 |

BC559 |

| 2 |

D1, D2 |

1N4001 |

| 1 |

D5 |

LED |

| 1 |

J3 |

3 pole foot switch |

| 3 |

POT1-POT3 |

10k |

| 1 |

RV1 |

1k |

| 1 |

X1 |

20Mhz Crystal |

I hope you enjoyed reading this article as much as i enjoyed building this pedal and hope to hear from you. To the subscribers, the newsletter will be sent in a few days with Gerber files for PCB and MCU firmware and a couple more details about this construction.

This sure was a pretty full period audio-wise. Lots of events all over the world and im glad to say i pushed forward new developments with Project Ryu.

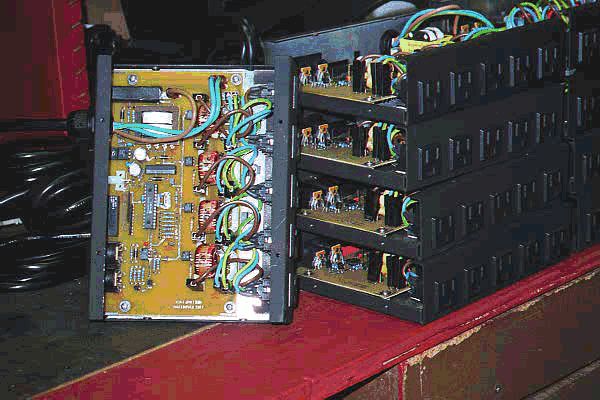

CEATEC Exhibition as expected was held this month and i was looking forward to some new audio products. Looking around i found Tamura Booth showing off their transformers. In a glass box they also had one of their vintage jewels. Take a look:

Next interesting booth was Pioneer’s. A lot of demo DJ setups and noise but in a corner i found TAD. Nothing new here but i could snap a couple of driver close-ups of the Reference One Speaker System. Also they displayed the Compact Reference CR1MK2 but i got to say i was more attracted by a TL-1601a they had in between.

Next to TAD, Pioneer Professional (… i know) showed their PA speakers. GS-WAVE Series sure look promising and it is a pretty interesting move for Pioneer to go back to the old days of PA with the concept for this series. Pictured below is the WAV-LENS, mid-high speaker featuring acoustic lens and can do a whooping 145dB peak. Coaxial 2″ drivers, 250W MF and 160W HF and dispersion measures 110 deg H and 50 deg V.

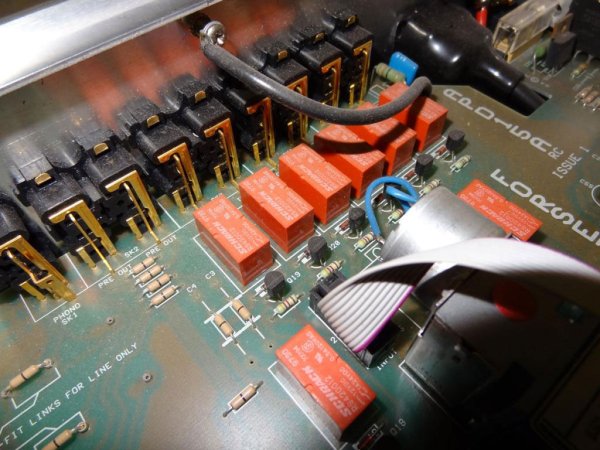

Technics had a very nice room, showing a bit of their history, had 2 listening rooms and they presented their Reference System R1 Series. Products were displayed with inside view as well.

The R1 Series has 3 components, SU-R1 Network Audio Control Player (aka Preamplifier), SE-R1 Stereo Power Amplifier and SB-R1 Speaker System.

Technics SU-R1 Control Amplifier is a 17kg preamp featuring Technics Digital Link (a digital connection between Technics Components) and it is powered by two R core power transformers.

![Project Ryu Lagger Guitar Pedal Take 3]() SE-R1 Stereo Power Amplifier sure looks like it can handle the work load. Normally Technics tried to come up with something different and even if IMHO they really lack imagination naming these technologies, i really appreciate their effort. So SE-R1 features JENO Engine (Jitter Elimination and Noise-shaping Optimization) … [great name guys!], GaN-Fet Driver, (now this is something worth looking into) and LAPC (Load Adaptive Phase Calibration).

SE-R1 Stereo Power Amplifier sure looks like it can handle the work load. Normally Technics tried to come up with something different and even if IMHO they really lack imagination naming these technologies, i really appreciate their effort. So SE-R1 features JENO Engine (Jitter Elimination and Noise-shaping Optimization) … [great name guys!], GaN-Fet Driver, (now this is something worth looking into) and LAPC (Load Adaptive Phase Calibration).

The third component of the R1 Series is the SB-R1 speaker system. Now in the past Technics has proven its speaker design ability with some really amazing products. Now on this blog i don’t really want to write subjective impressions on sound so if you are curious about this system go ahead and find a place where you can listen to them. And this goes for any system from any brand, its your money, if your willing to spend it go and decide for yourself.

What i can do is give you some pictures and info on how these systems are built. So back to Technics SB-R1, these speakers claim 100kHz , and they reach that but at -16dB! Oh well… so lets just throw away the specs and look at what we have here.

We have 4 x 16cm drivers in 2 separated bass reflex enclosures (2 per enclosures), we have 1 coaxial MF/HF unit which looks pretty interesting in its own isolated closed enclosure.

Below you can see a cutout through the speaker and some details like crossover board. As you can see there are no exotic components in the crossover.

For more detail: Project Ryu Lagger Guitar Pedal Take 3

The post Project Ryu Lagger Guitar Pedal Take 3 using pic microcontoller appeared first on PIC Microcontroller.